Expansion Joints

Critical to keeping openings between connected structures in your building watertight, expansion joints keep these unprotected and inaccessible areas safe from water damage that can cause a weakened building structure, interior damage, mold conditions, or a host of other issues.

Expansion joints should last 10-20 years, but we recommend inspecting them annually to ensure all components are intact and to avoid costly water damage.

Why Invest In Expansion Joints

Accessing a small gap between two buildings is impossible,

but sometimes it has to be waterproofed.

Walls that are concealed may have water entering either one or both structures as a result of failed waterproofing. In many cases, openings between connected building structures are often too wide or move too much, requiring something more than caulking to remain watertight.

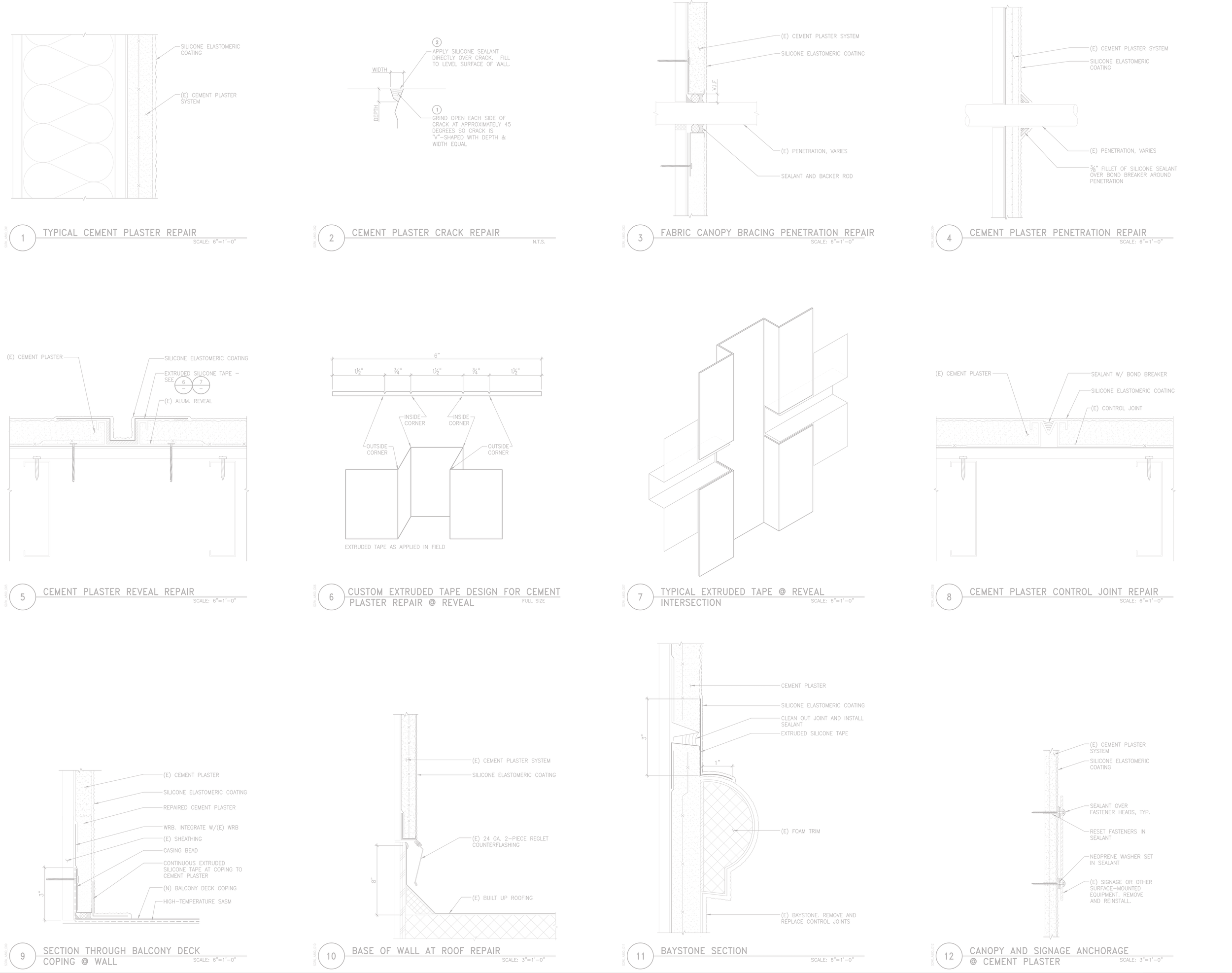

Connecting straight pieces and achieving turns and right angles are where the art of expansion joint installation lies. An expert installer knows how to connect these pieces to make sure no breaches in the joint occur under movement stress.

Here are some things to consider to set your expansion joint waterproofing project up for success:

What are the joint dimensions? An experienced expansion joint tech knows that joint dimensions can vary, even along the same joint. Knowing all the required sizes for the joint(s) avoids surprises and cost overruns.

How much movement is there? You need to know how much the joint is expected to move in order to select the right material and account for all of the expansion you will need.

What level of fire protection do you need? Your contractor should be able to help you choose the right type of expansion joint to meet any fire code requirements.

Types of Buildings We Work On

SUCCESS STORIES

We protect your building envelope from the elements

Services

-

Expansion joint systems that have rails that attach to the joint walls and bar-arms that connect them, covered by a membrane. They can have a fire blanket and water blanket assembly below and a cover plate on top.

-

Foam and rubber expansion joints are installed in a compressed state and expand after the encasing plastic is removed. These are attached to joint walls with adhesive and via compression.