Multi-phase restoration for the iconic Transamerica Building

Transamerica Building

600 Montgomery Street

An iconic landmark in San Francisco that is instantly recognizable, the exposed precast concrete exterior cladding had spalled and cracked through years of weathering. Due to the unique geometry of the building, access to the repairs required some ingenuity. A custom swing stage access system was engineered and implemented by installing anchors at each corner of the building; the anchors allow the swing stage to be moved laterally to reach the entire building from corner to corner. The swing stage was rigged with outrigger beams that went through removed louvers on top of the building. This can be seen in aerial views in several Hollywood movies that take place in San Francisco.

“Testimonial from client or Urban Co team member that highlights the most important thing about the job.”

What We Did

Concrete crack injection.

Sealant replacement.

Pressure wash the entire building

Clear penetrating sealer

Concrete spall repairs

Project Details

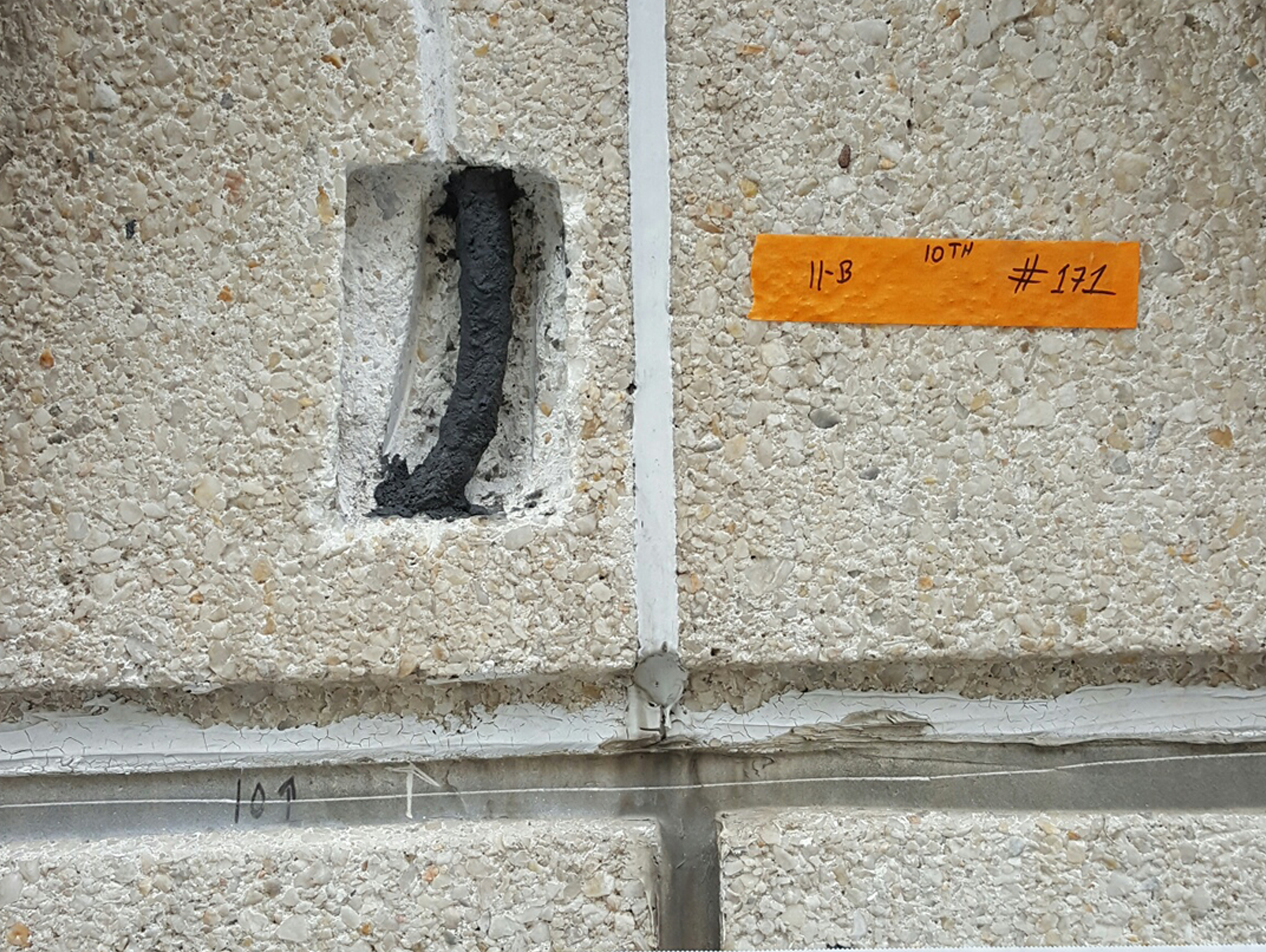

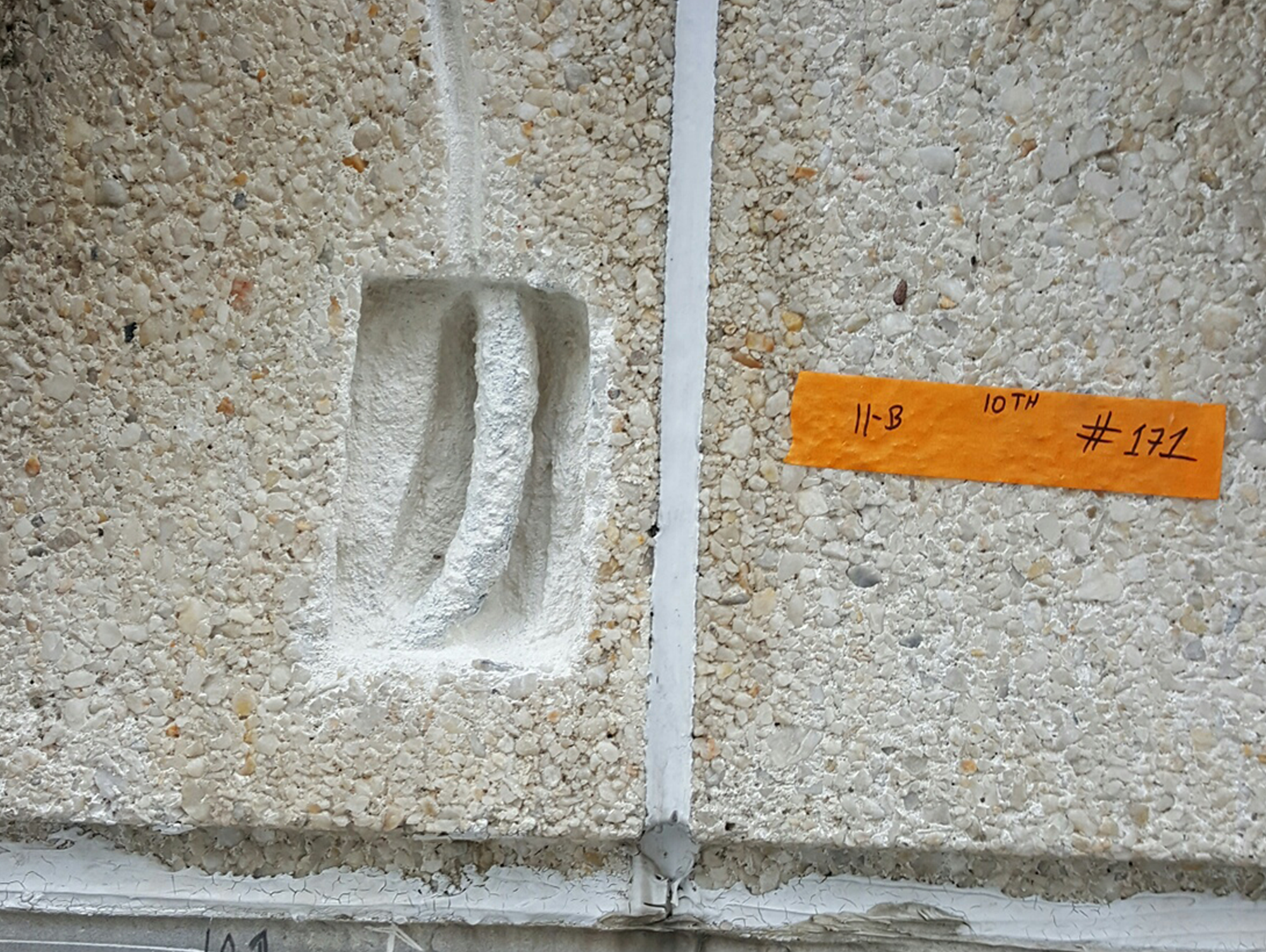

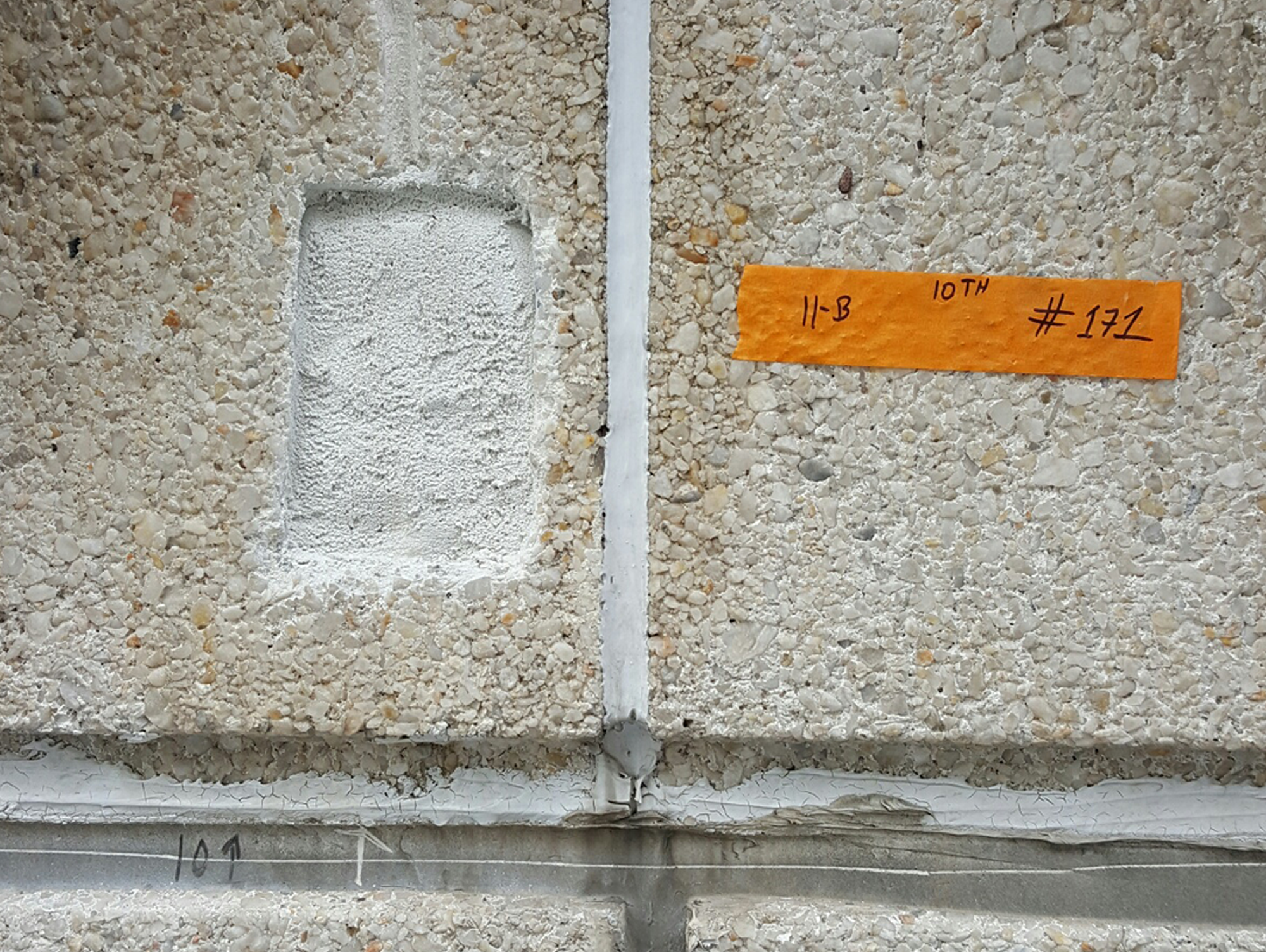

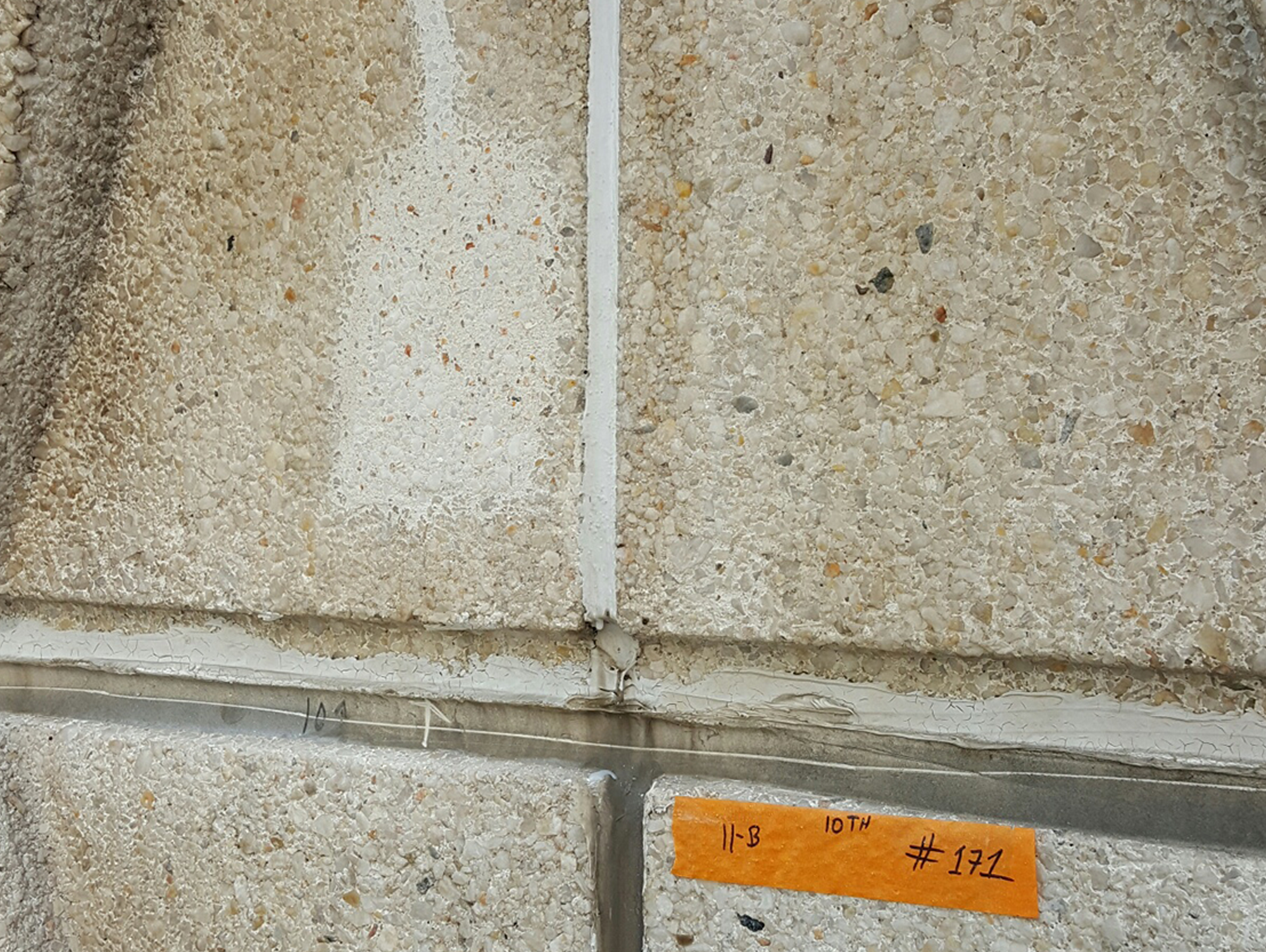

This three-year-long restoration project had a humble beginning. Urban Waterproofing was originally hired to perform exterior leak repairs at three windows. Once we gained close-up access to the building exterior, we observed concrete deterioration such as spalls and cracks and reported the conditions to the owner. Urban was retained by the owner to survey the entire building and perform repairs as necessary. Given the iconic status of the buildings, the appearance and quality of the repair work were paramount. In order to create matching concrete for spall patches, pieces of spalled concrete from the building were sent to Connecticut for analysis and custom matching. After a painstaking mockup and review process, a near-perfect result was achieved. The patches were almost indistinguishable from the original concrete. Other repairs include epoxy injection of cracks as well as replacement of failed sealant.

After the repairs were completed, the entire building was pressure washed and treated with a penetrating clear sealer to reduce moisture absorption in the concrete.

Want to know how we can help with your next project?