Custom made solution to bring severely deteriorated sealants back to life

Lawrence Berkeley National Lab Building 2 (LBNL)

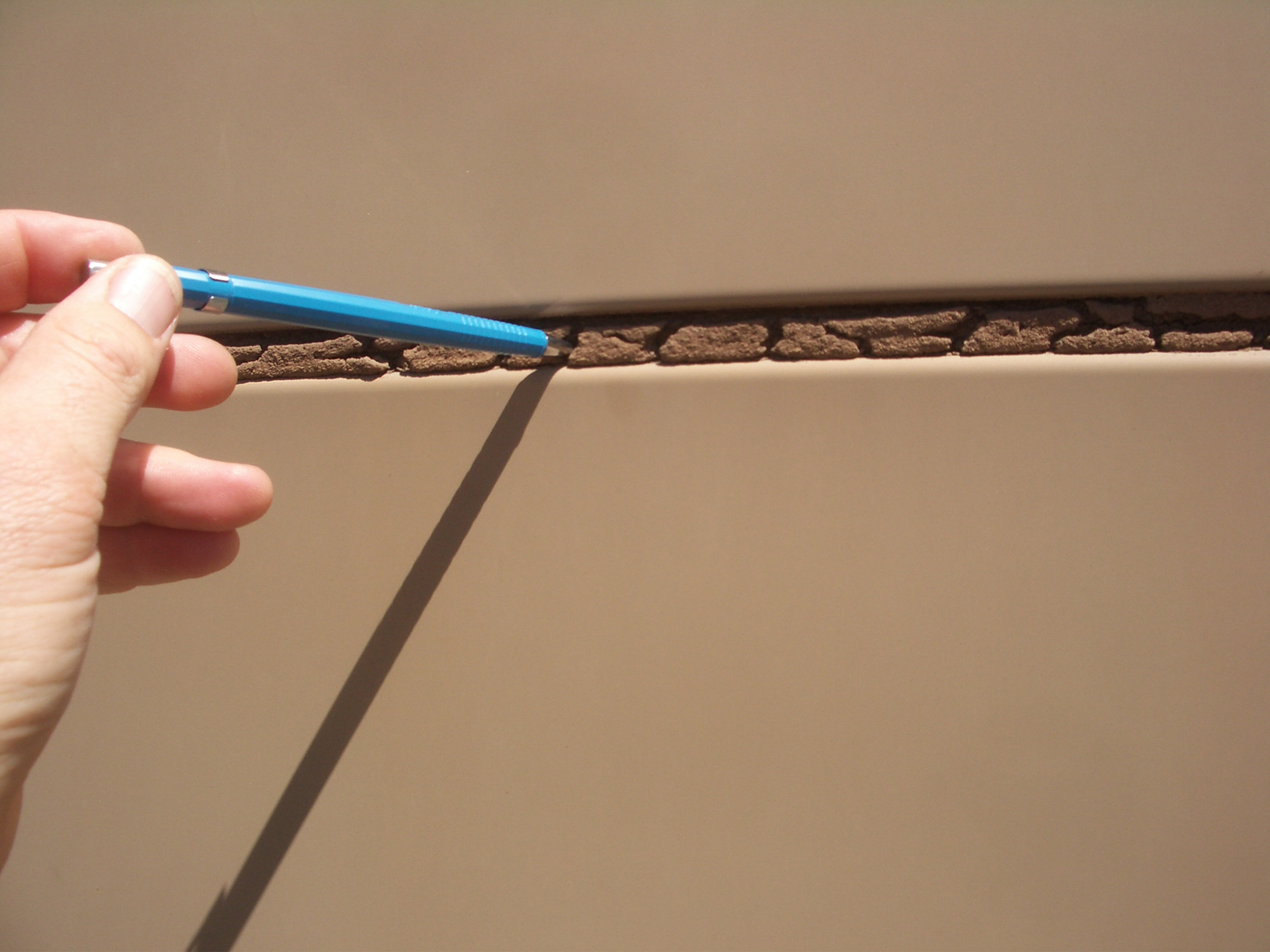

Building 2 is a metal-clad structure that is part of the Lawrence Berkeley National Lab complex. Over the years, all of the sealant used to connect the metal panels to each other had become severely reverted and deteriorated, to the point where it was not functioning at all. Water was able to easily bypass the sealant joint and enter the wall cavity. This job had a variety of challenges, one of which was matching the color of the new sealant to the factory-finished metal panel color. The team did not want the new sealant to stand out too much, making the building look like a gingerbread house. In addition, the safety requirements at that location were incredibly stringent, and with 5 stories of scaffolding being built, work at every inch of the building going on, and at times over 30 workers on the project at once, the oversight had to be impeccable. In addition to replacing the sealant, Urban performed a tuneup on the casement and pivot-type windows, requiring the fabrication and installation of custom window gaskets and custom machined hinge sets.

There are times when a building or project dictates custom solutions and field adaptations for a successful project. In this case, almost all components—the sealant, the window gaskets, and the window hinges—had to be custom-made. This brings risk if measurements / quantification are off at a project of this scale, but if done properly, in the hands of a capable and inventive contractor, it provides a one-of-a kind solution for the Owner.

What We Did

Installed over 30,000 lf of custom-colored silicone sealant at windows and metal panels

Fabricated and installed over 300 custom window gaskets and nearly 6,000 rf of weatherstripping.

Designed, fabricated, and installed 100 aluminum pivot window hinges.

Project Details

Work to perform the waterproofing repairs designed by Simpson Gumpertz & Heger was performed while the lab was fully occupied and in use. This meant careful phasing and planning to work around key areas where research was in progress, and construction interruptions weren’t an option. The team was under constant supervision from the LBNL EH&S Dept. (Environmental Health and Safety), on the lookout for any infraction that would impact their safety record. Work in these conditions is oftentimes challenging enough, made more so by an inspector constantly watching you (with binoculars!), waiting for you to make a mistake.

To match the color of the panels, first a paint match was made to the panel color, and then the approved match was sent to Dow Corning to match their silicones. Samples were shipped out, and once approved, the bulk order could be placed.

With the scaffold in place and a safety plan approved and in place, work could begin to remove the sealant. Most joints were easily accessible, but since EVERY joint and plane change had to be replaced, the workers sometimes had to perform yoga just to gain access to corners and joinery tucked back into recessed window cavities.

While the sealant replacement was underway, all 350 windows in the building required a tuneup; in some cases, the windows simply needed cleaning and the hinges lubricated. In other cases, the custom hinges were damaged, out of working order, and in need of replacement. The problem was that these hinges were custom-made when the building was erected and are no longer available from any source at any cost. So, we had to take an existing hinge set off and have a machine shop custom make new hinges. These are two-part interlocking hinges—nothing like a typical hinge. The windows, at over 80 pounds each, put a tremendous amount of stress on the hinges, and any miscalculation in the measurement would cause misalignment, and the windows wouldn’t seat properly for a tight weatherseal and open/close sequence. The mold for the hinges had to be perfect; once struck, it would be used for the 125 hinges that were eventually machined for this project.

Also part of the window tuneup were the replacement of the window gasket and weatherstripping, which were required to ensure the windows were weatherproofed. Again, profiles and designs for these components were no longer available, so we had to remove existing ones and fabricate new ones to match.

Ultimately, the custom silicone sealant and silicone tape fabrication and installation and the fabrication and installation of the custom window components came together under the watchful eye of both the Urban Waterproofing and LBNL EH&S departments for a successful outcome.

Want to know how we can help with your next project?